Posted on May 6, 2024

Unleashing the Power of Precision: The Benefits of Laser Micromachining Services

Image Source: Google

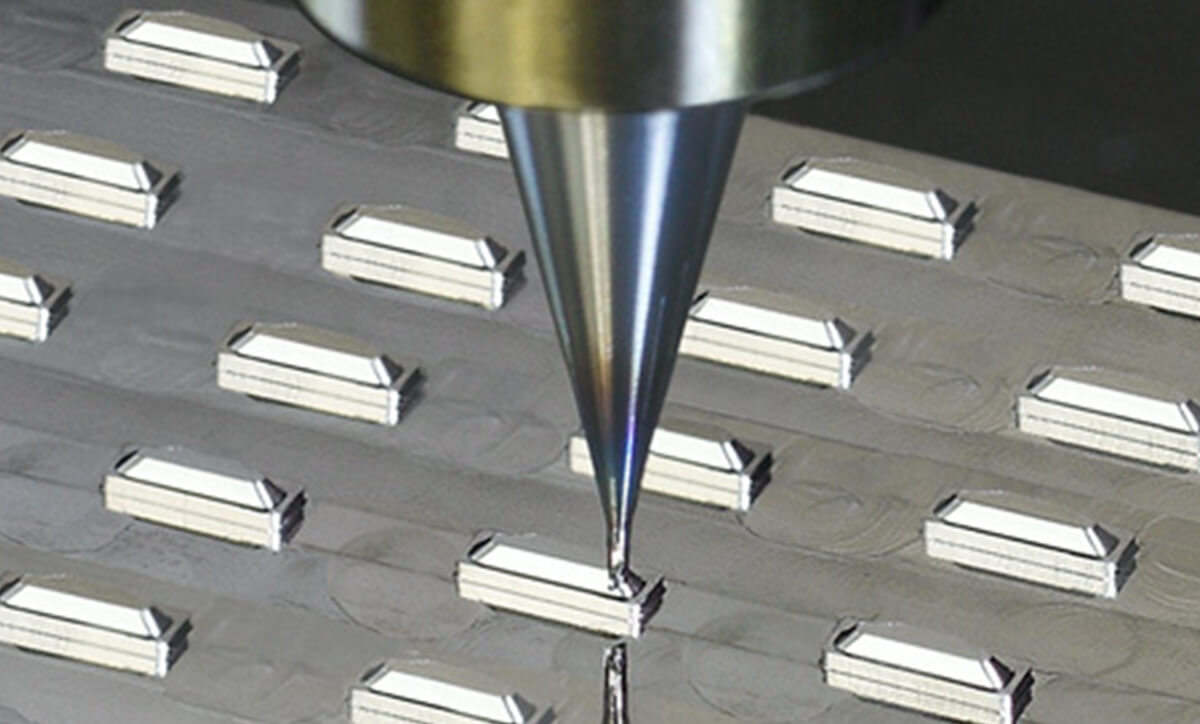

Laser micromachining is a cutting-edge technology that has revolutionized the way precision manufacturing is done. By utilizing high-powered lasers, manufacturers can achieve incredibly precise cuts and engravings on a wide range of materials. This article will explore the benefits of laser micromachining services and how they can help businesses in various industries unleash the power of precision.

The Technology Behind Laser Micromachining

Laser micromachining involves using a focused laser beam to remove material from a workpiece, creating intricate designs, patterns, or cuts with extreme precision. The process is computer-controlled, allowing for high levels of accuracy and repeatability. Different types of lasers can be used for micromachining, including fiber lasers, CO2 lasers, and UV lasers, each with its own strengths and applications. If you are looking for the best laser micromachining service then, you may visit this site.

Key features of laser micromachining technology:

- Precision: Laser micromachining can achieve feature sizes as small as a few microns, allowing for intricate and complex designs.

- Non-contact process: The laser beam does not physically touch the workpiece, reducing the risk of contamination or damage.

- Versatility: Laser micromachining can be used on a wide range of materials, including metals, plastics, ceramics, and composites.

- Speed: The high-powered lasers used in micromachining can remove material quickly, leading to faster production times.

The Benefits of Laser Micromachining Services

1. Precision and Accuracy

One of the primary benefits of laser micromachining services is the unparalleled precision and accuracy they offer. With the ability to create features as small as a few microns, laser micromachining can achieve levels of detail that are simply not possible with traditional machining methods. This precision is essential for industries such as electronics, medical devices, and aerospace, where tight tolerances are required.

2. Versatility

Another key benefit of laser micromachining services is their versatility. Whether you need to cut, drill, engrave, or ablate materials, laser micromachining can handle a wide range of applications on various materials. This versatility makes it a valuable tool for manufacturers in industries such as automotive, semiconductor, and consumer electronics.

3. Reduced Heat-Affected Zone

Unlike traditional machining methods that can generate a significant amount of heat, laser micromachining is a non-contact process that produces minimal heat-affected zones. This is particularly important for materials that are sensitive to heat, such as plastics or thin films. By minimizing thermal damage, laser micromachining helps preserve the integrity of the workpiece and produce high-quality results.

4. Cost-Effectiveness

Despite being a cutting-edge technology, laser micromachining services can be cost-effective for businesses in the long run. The precision and efficiency of laser micromachining can lead to reduced scrap rates, lower rework costs, and faster production times. Additionally, the non-contact nature of the process reduces tool wear and maintenance expenses, saving money over time.

Applications of Laser Micromachining

Laser micromachining services have a wide range of applications across industries. Some common applications include:

- Microelectronics: Laser micromachining is used to create precise features on semiconductor wafers, circuit boards, and microchips.

- Medical Devices: From stents and catheters to surgical instruments and implants, laser micromachining is crucial for manufacturing medical devices with intricate geometries.

- Aerospace: Laser micromachining is used to fabricate components for aircraft engines, satellites, and other aerospace applications that require high precision and reliability.

- Consumer Electronics: Laser micromachining is used to manufacture components for smartphones, tablets, and other electronic devices with small form factors.

Conclusion

Laser micromachining services offer a unique combination of precision, versatility, and cost-effectiveness that make them indispensable for businesses in a wide range of industries. By leveraging the power of laser technology, manufacturers can achieve levels of accuracy and detail that were once thought impossible. Whether you are in the electronics, medical, aerospace, or automotive industry, laser micromachining services can help you stay ahead of the competition and unleash the power of precision in your manufacturing processes.